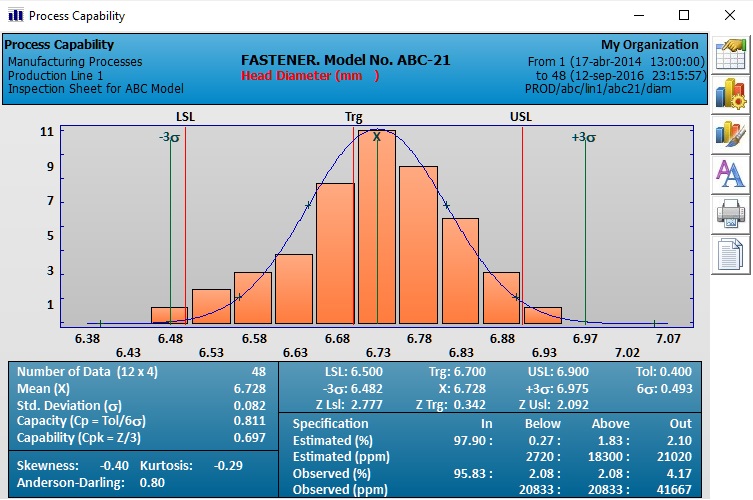

Through the process capacity study, SuperCEP lets you know

how probable it is to meet the specifications and tolerances required by the customer.

This study is based on the statistical theories of the

Normal and Non-Normal frequency distributions.

The automatic header fully identifies the source of

the study data.

In the graphic section you have: * Histogram with frequency

scale and class marks. * Indicators of the mean, standard deviation, target, specification limits and

natural variability 6 sigma zone. * Theoretical Normal curve.

In the numerical section you have: * Mean and Standard

deviation. * Tolerance, Variability and Cp Potential Capacity. * Standard z's and Cpk Process

Capability Index. * Bias, kurtosis and normality fit analysis. * Theoretical and observed nonconforming

population.

|

The system will calculate for you the indices of Capacity

Cp - Cpk, Performance Pp - Ppk and their inverses Cr - Crk and Pr - Prk. Likewise, the Machine Capacity

Cm - Cmk and the Capacity of Taguchi Cpm - Cpmk.

Using the button ribbon you can: * Export the study to another

program. * Reconfigure parameters and scope. * Change colors and fonts. * Print the study..

Within the configuration options you will vary:

* Start and end date. * Number of intervals. * Confidence level from 1 to 6 sigma. * Data filter.

* Normal or Non-Normal Analysis. * English, Spanish, Portuguese, Chinese, French or Swedish language..

A Collective Histogram can also be obtained in which

you will simultaneously analyze all the quality characteristics on a single screen. In this way

it is quickly appreciated which variable or attribute requires the most attention. The Stratified

Histogram displays segmented views to detect variations between shifts, operators, materials, or

any other variable or attribute.

|