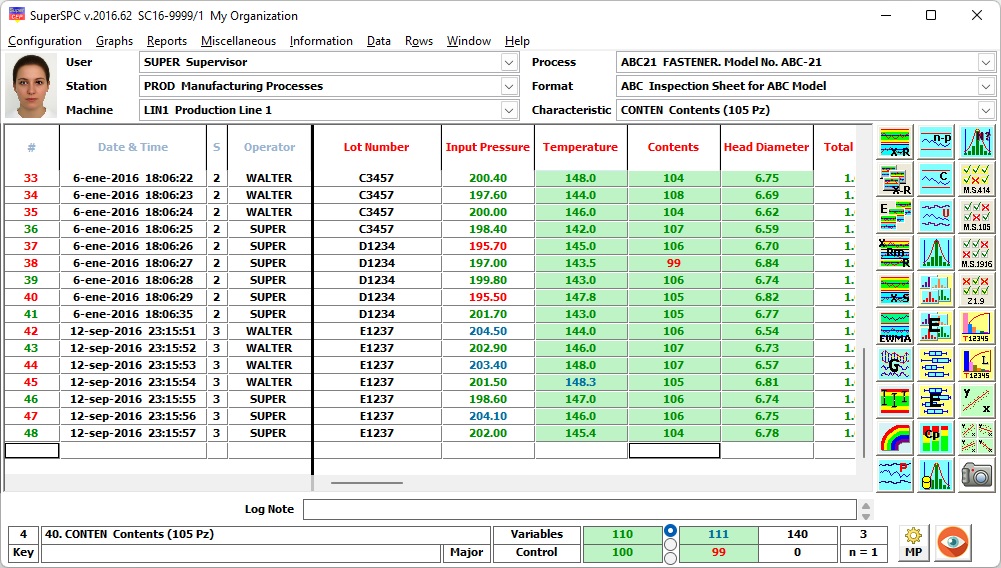

The electronic Inspection Sheets capture, label,

order and store quality sample data.

The entry to each sheet is granted to users

according to their level of access and specific need. In this way the integrity of the

data is protected and the operation of the system is facilitated.

The identification is shown in the header of each sheet:

* User. * Station or Department. * Machine, Line or Area. * Product, Process or Service.

* Inspection format. The keys and names of these elements are fully configurable.

On the inspection sheet, each line represents a sample

automatically labeled with: * Number. * Date and Time. * Production shift. * Operator / Inspector.

These data can be modified only by authorized users.

Each column of the inspection sheet represents a variable

or attribute characteristic to control. The sheet receives variable data, attributes, free identifications,

dates, times and calculated values.

You can define from 1 to 250 columns per sheet.

At its bottom appear the most important data of the Characteristic that is being measured

as the cursor is placed on each column.

|

The values of the specification, statistical and input limits,

the input mode and the sample size, among other important data, are clearly shown.

Out of specification data is clearly indicated. Wrong or badly

captured data is automatically deleted.

To each sample you can attach a free comment to build the

log of the process.

In the menu bar you have direct access to the editing,

importing, exporting, configuration and reporting functions.

On the right side is the list of charts available for

each user according to their level of analysis and decision..

At any time you can request particular information

about each characteristic of the sheet such as formulations, operating conditions, equipment

setup and starting routines, inspection methods, etc.

|